Paper of Medium Thickness |

Thin Paper |

Most of the Admiral stamps were printed on unwatermarked wove paper of medium thickness. Thin paper, having a grainy appearance, which is best seen by looking at the gum side of the stamp, was used for experimental purposes in a few production runs in October 1924.

Paper of Medium Thickness |

Thin Paper |

Two versions of the reason for the use of this paper are on record. One maintains that there was an experiment in the printing to reduce the price of paper, which was purchased by weight. The official explanation is that the Canadian Bank Note Company merely used paper not up to specifications. That the paper was in fact used in an experimental manner, however, does not appear to be refuted.

Heavier paper, as compared with the early issues, was used for issues after 1925, but the difference is insignificant.

Methods of Printing |

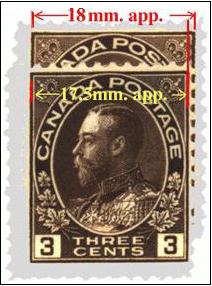

Two methods were used to print the Admiral issue: Wet and Dry. Until December 1922, the wet process was used to print all Canadian postage stamps. With this method, the printing is carried out while the paper sheets are still damp. The gum is applied after the sheets have dried. The sheets are then severed into panes and perforated. The chief advantage of the dry process, so named because the printing is done on on dry, pre-gummed paper, is speed of reproduction. Stamps printed by either process are readily identified by comparing their horizontal widths or vertical heights. As shrinking occurs when sheets used in the wet process dry, stamps made with this method are narrower than their dry printed counterparts, if vertical wove paper is used, and shorter, if printed on horizontal wove paper. The latter is particularly evident with the early issue booklet panes, which were all printed on paper with the grain running horizontally. |

The illustration depicts the effect of horizontal shrinkage caused by the wet printing process. The printing process for all denominations did not occur all at once; by January 1926, however, all printing was being carried out using the dry method.

Updated: 5 Oct 97